How Membrane Switches Ensure Reliable and Efficiency in Electronics

How Membrane Switches Ensure Reliable and Efficiency in Electronics

Blog Article

Why Membrane Layer Changes Are Vital for Sturdy Control Systems

Membrane layer switches play an essential function in making sure the resilience and integrity of control systems across different industries. Their distinct construction permits them to withstand tough ecological factors such as moisture, temperature extremes, and physical wear. This strength not only prolongs the life-span of the systems they serve but additionally minimizes maintenance requirements. As we discover the multifaceted advantages of membrane buttons, it ends up being evident that their significance transcends simple capability, affecting customer experience and functional effectiveness. What further effects do these qualities hold for the future of control system design?

Review of Membrane Layer Switches

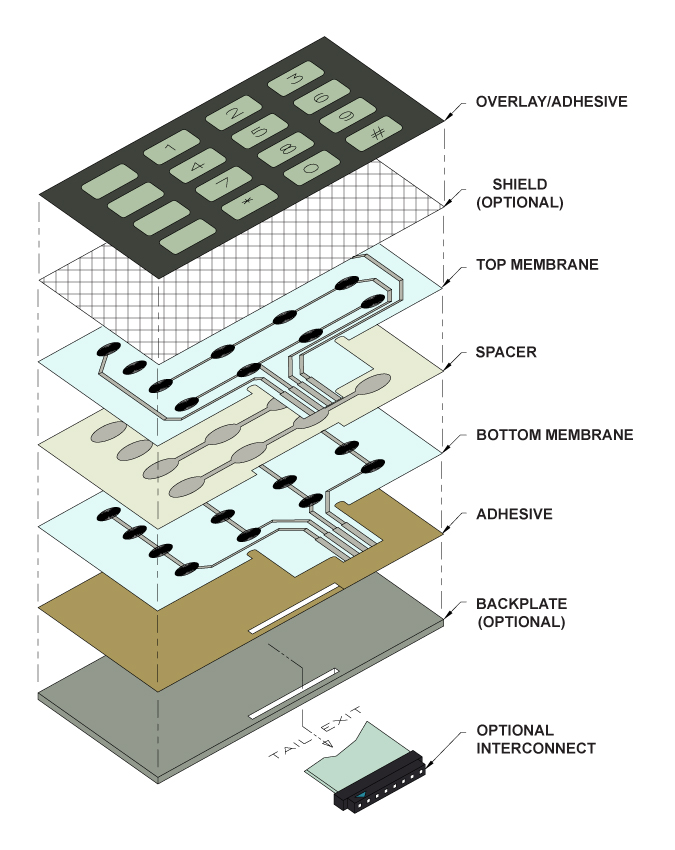

Membrane buttons are versatile and reliable parts frequently made use of in numerous electronic control systems. These switches contain a number of layers, consisting of a visuals overlay, a spacer layer, and a published circuit layer. The graphic overlay supplies both functional and visual style, while the spacer layer guarantees that the buttons are turned on only when pressed. The printed circuit layer includes conductive traces that complete an electrical circuit when the membrane layer is pressed, allowing the tool to react to individual inputs.

Membrane layer switches are often preferred in applications calling for a small and lightweight design, making them excellent for portable devices, clinical tools, and industrial equipment. They can be personalized to satisfy particular customer needs and can integrate various features such as backlighting, tactile responses, and numerous colors. Furthermore, membrane buttons are resistant to dirt, wetness, and contaminants, making them ideal for environments where toughness is essential.

Advantages of Resilience

In several applications, the sturdiness of membrane changes offers substantial advantages that enhance their general efficiency and dependability. These switches are created to hold up against severe environments, making them optimal for usage popular conditions such as high moisture, extreme temperature levels, and exposure to chemicals. Their robust construction helps to avoid damage from physical influence, guaranteeing long-lasting functionality and minimizing the requirement for regular replacements.

Furthermore, membrane layer switches are resistant to wear and tear, which is critical in applications where constant communication takes place. This durability converts to decrease maintenance expenses, as organizations gain from lowered downtime and less solution disruptions. Additionally, the encapsulated design of membrane layer switches over shields interior parts from dirt and wetness ingress, further contributing to their life expectancy.

Another benefit is their capability to preserve constant performance over time. With a high tolerance for mechanical stress, these buttons maintain their responsive feedback and electrical stability, guaranteeing customer contentment. Eventually, the toughness of membrane layer switches over not just improves operational performance yet likewise cultivates confidence in their reliability, making them a favored choice for control systems throughout numerous fields.

Applications in Different Industries

Resilient control systems employing membrane buttons locate considerable applications across a series of markets, each gaining from the unique attributes these switches supply. In the medical industry, membrane layer buttons are vital for devices such as patient displays and diagnostic devices, where integrity and simplicity of cleansing are critical. Their resistance to wetness and this hyperlink contaminants ensures they maintain performance in clean and sterile settings.

The vehicle sector leverages membrane buttons for dashboard controls and infotainment systems, where they supply sleek, low-profile interfaces that improve user experience. These buttons are also made to withstand severe problems, including exposure to extreme temperatures and vibrations.

In industrial settings, membrane buttons are typically made use of in machinery control board, providing responsive comments and resilience needed for high-usage applications. Their capability to stand up to chemicals makes them ideal for making environments where spills and contaminants are frequent.

Consumer electronic devices, such as cooking area home appliances and push-button controls, likewise make use of membrane switches for their flexibility and cost-effectiveness. On the whole, the flexibility and robust nature of membrane switches make them vital throughout various industries, ensuring efficient procedure and long life in control systems.

Style and Visual Charm

While capability is paramount, the layout and aesthetic charm of control systems equipped with membrane layer switches play a vital function in user engagement and overall experience (membrane switch). The aesthetic design of these buttons can considerably affect user understanding and interaction. A well-designed membrane button enhances the beauty of the tool, making it much important site more attractive to customers and promoting a link in between the individual and the product

Membrane switches provide a lot of adaptability in design, enabling manufacturers to tailor graphics, shades, and textures to align with brand identification and item looks. The use of dynamic shades and distinct patterns can attract attention, while responsive responses can reinforce the user's interaction with the device. Additionally, the ability to integrate LED indicators and backlighting right into the membrane button design offers both functional and aesthetic benefits, improving presence and use in different settings.

Enhancing User Experience

Additionally, membrane layer switches can be customized to incorporate graphical interfaces, boosting functionality by presenting info in a clear and user-friendly manner (membrane switch). This personalization can include symbols, labels, and shade coding that guide customers via complex functionalities with convenience. Additionally, their convenience enables combination in various environments, ensuring regular efficiency whether in commercial equipment or customer electronic devices

The sturdiness of membrane layer buttons also plays an important duty in individual experience. By standing up to extreme conditions and extended usage, these buttons minimize the chance of system failings, hence promoting dependability and customer confidence. Ultimately, the strategic usage of membrane layer changes not only raises performance but also substantially improves user interaction special info with control systems, making them a vital part in contemporary style.

Verdict

Report this page